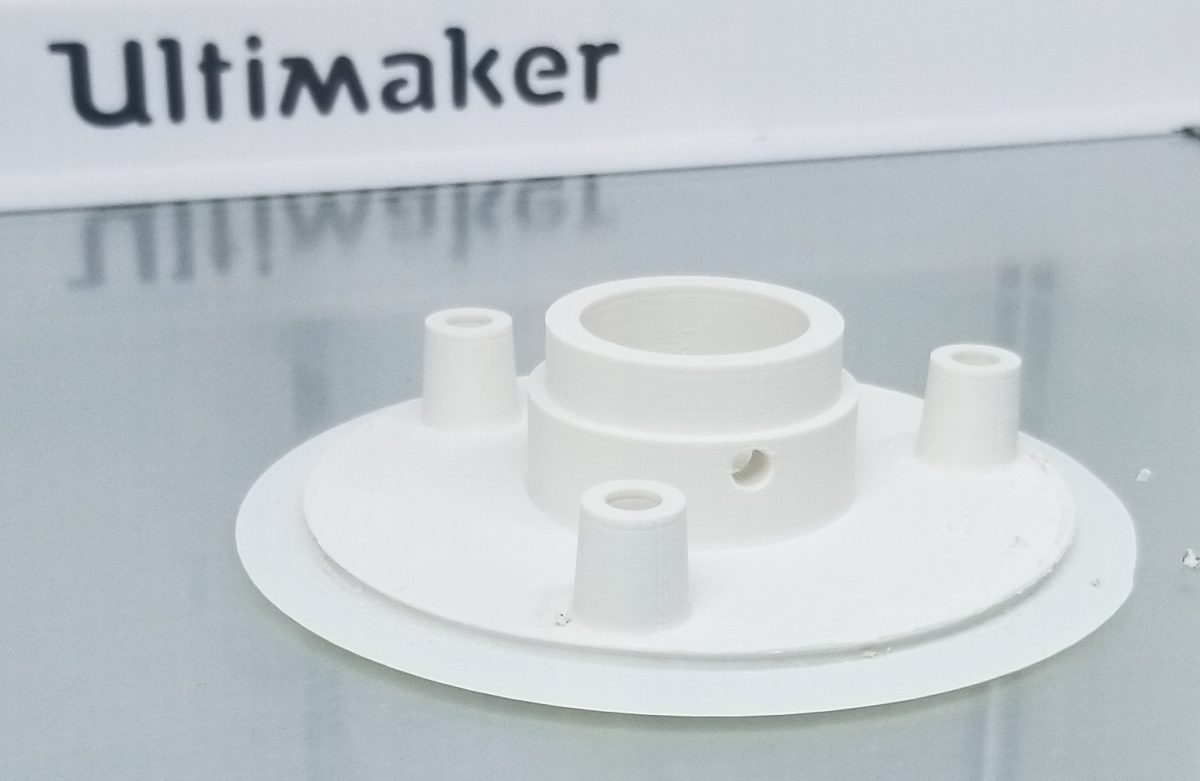

Trying out a new filament for the first time on the Ultimaker S5. Unfortunately we are currently unable to use ASA as the filament choice on the print station so we used generic ABS instead.

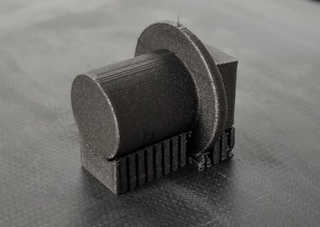

When we used glue stick for the actual first test the print warped part way into the print.

The bed was cleaned and a generic hair spray was sprayed on the print bed. No problems with warping.